Wyma Solutions

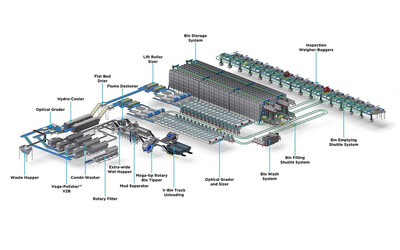

Wyma designs, manufactures, distributes and services post-harvest vegetable and fruit handling equipment and solutions worldwide. At Wyma, we recognize that each customer has different needs, produce varieties, growing conditions and scales of operation. With a strong emphasis on collaboration, our team configures and tailors post-harvest solutions to match your specific conditions and requirements. As part of our commitment to creating post-harvest solutions that deliver long term value Wyma partners in Australia and New Zealand with other quality equipment providers Burg Machinefabriek, Manter International B.V. and Flikweert Vision. Burg excels in providing automation and optimization solutions for sorting, packaging and logistics of fruits and vegetables. -Manter is a leading manufacturer of weighing and packing machines for potatoes, vegetables and fruit. -Flikweert Vision develop smart machines that can automate and simplify production processes with the help of artificial intelligence. This results in more stable productivity and significant labour cost savings. The Wyma team prides itself on designing full line solutions for customers. We focus on delivering a turn-key solution – it’s not just about individual pieces of equipment in the line, we provide integration and automation of equipment including support structures, conveyors, electrical integration and programming. Wyma is an award-winning exporter with a reputation for operational excellence, quality and innovative product design and manufacturing processes. We aim to provide the best solution to minimize downtime, reduce waste and get the best from every harvest. Wyma has production facilities on three continents and sells equipment and line solutions in more than 90 global markets. Wyma Solutions is known globally as a trusted provider of post-harvest equipment.

Canadian farm chooses Wyma Solutions for post-harvest processing

Canada's ATV Farms has selected Wyma Solutions to deliver two large post-harvest vegetable grading and packing lines for carrots and onions.

Large carrot grower and packer values collaborative approach

Kalfresh applies the same philosophy in the field, in the packing shed and in marketing: "Innovate to keep growing".

Carrot line upgrade results in increased demand for the product

Wyma Solutions installed a post-harvest 15 t/h carrot line for B.D. & M.D. Nicol & Son, which resulted in increased demand from supermarkets for its carrots.

Wet Bunker Storage system for Moffatt Fresh Produce

The idea of the Wyma Wet Bunker Storage system was first floated to Steven Moffatt of Moffatt Fresh Produce by Wyma Solutions' National Sales Manager, John Roest.

Ivankovich Farms meets shelf life and quality requirements for carrot export markets

The time had come to review Ivankovich Farms' packhouse operation to meet the challenges of exporting a perishable product over a long distance.