Getting the right balance of water content in butter

In modern dairy processing, precision is no longer just a mark of quality but a key economic factor. This is especially evident in butter production, where the moisture content must be carefully balanced.

Depending on production conditions and process parameters, the moisture content can vary between 15 and 17%. However, the legal limit in the European Union is 16%. If the moisture content exceeds this threshold, the product cannot be sold.

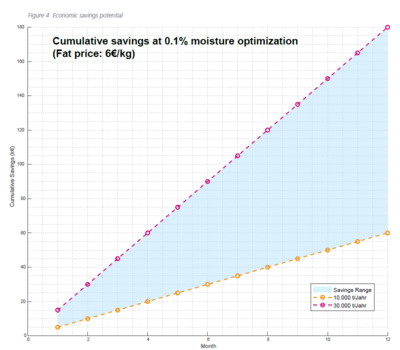

To avoid exceeding the legal limit, many manufacturers intentionally set a lower target moisture content, typically between 15 and 15.5%. However, this precautionary buffer reduces profitability as even a slight decrease in water content increases the fat proportion in the product. Moreover, insufficient moisture can negatively impact butter quality, compromising spreadability and leading to an undesirable texture.

Continuous moisture measurement directly within the production line is therefore essential for butter production. Only with real-time monitoring can water addition be automatically regulated, enabling butter to be optimised for consistent quality and maximum efficiency.

Berthold Technologies has released a new white paper which examines the practical application of the MicroPolar LB 566, a microwave measurement system designed to determine moisture content in butter. The system is designed to deliver non-destructive measurements using microwave technology and is engineered for seamless inline integration into dairy production processes. The goal is to provide manufacturers with a solution to increase yield, ensure product quality and comply with legal requirements.

The measurement system generates microwaves that interact with the water molecules due to their high dielectric constant. This interaction causes an attenuation of the microwave energy, which can be detected as phase shift and attenuation. Since the phase shift and attenuation change are directly proportional to the water content in the product, the concentration or solids content in the medium can be determined with accuracy. The multi-frequency technology from Berthold is designed to be unaffected by interfering reflections or resonances from the measuring environment.

For more information, visit: www.berthold.com/dairy

SPC Global to close facility under demand-led manufacturing strategy

SPC Global plans to close its Mill Park facility in Victoria by August 2026 and relocate...

Unlocking the benefits of avocados across the value chain

Westfalia Fruit is helping to advance the future of the avocado sector with its zero-waste,...

Risk management approach for toxin in infant formula

Following recent recalls of specific infant formula products, the European Food Safety Authority...