Cleaning adapted to the hygienic state of the machine

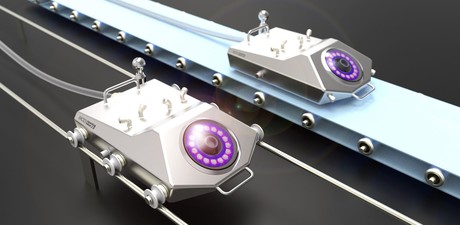

Fraunhofer IVV Dresden has developed a mobile device that facilitates the cleaning of processing machinery. The mobile cleaning device (MCD) brings together the benefits of traditional automated cleaning systems and the versatility of manual cleaning. It has an optical sensor system for dirt detection and adaptive cleaning.

What areas are dirty and need cleaning? When is the cleaning finished? Was it successful? In the future, these questions will be able to be answered using inline sensor systems.

The virtual twin of the MCD comprises an adaptive model of the cleaning process. Combining this with cognitive control concepts and the sensor system for dirt detection allows for adaptive cleaning — cleaning adapted to the hygienic state of the machinery.

The flexibility of the system is evident in the drive concept. Movement between machine modules can take place via a drive unit or by using existing transport systems such as conveyor belts. In contrast to standard cleaning systems, the MCD is not installed in a dedicated way in a machine; rather, it can be used in a versatile way to clean several machines. Separately driven nozzles are available for foam and spray cleaning. Besides the cleaning of whole machines, the targeted cleaning of parts of a machine is also possible.

Abattoir safety program in WA raises more awareness

Usage of knives and guarding of machinery were some of the key areas of focus in a recent...

Antimicrobial resistance in Aussie raw retail meats remains low, FSANZ survey finds

FSANZ has released its findings from a national survey of antimicrobial resistance in more than...

Heat and Control brings coffee and tea processing solutions to MICE 2026

Heat and Control will showcase its latest coffee and tea processing, packaging and inspection...