Pilot-scale process line to help progress beverage science

GEA is supporting hands-on training at Geisenheim University with process technology specifically designed for research and teaching. For the newly opened Beverage Technology Center (GTZ), the engineering group supplied a multipurpose plant that replicates industrial beverage processes on a small scale.

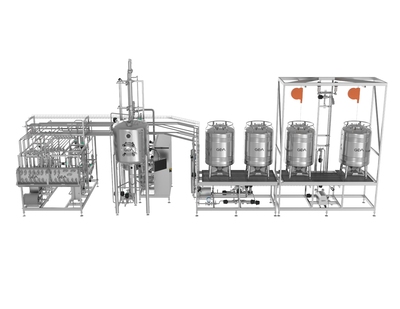

The pilot-scale solution combines industrial process standards with accessibility for teaching purposes. It consists of a flash pasteuriser, a cleaning-in-place (CIP) and sterilisation-in-place (SIP) system, a carbonator, an automated interconnection matrix, and a separator suitable for fruit juice, beer and wine applications. All components are skid-mounted, with an integrated maintenance walkway for optimal access — a set-up specifically adapted to the demands of university-based operations.

“Students should learn how processes work — and how to design them,” said Astrid Heller, project manager at GEA and expert for non-alcoholic beverage processing. “With this set-up, they can modify process sequences, understand control points, and at the same time gain insights into the hygiene and efficiency standards of industrial production.”

students how to think in processes. Michael Ludwig (second from left) heads the Beverage Technology Center for non-alcoholic applications. I

The automated interconnection matrix allows specific process steps to be switched on or off, enabling students and faculty to construct, modify and analyse entire process chains. This flexibility enables a learning experience that goes far beyond conventional training models.

“Our students not only experience real industrial automation here, but also develop a deep understanding of the logic and structure of modern beverage production — from pasteurisation to filling,” said Michael Ludwig, head of the GTZ at Geisenheim University.

“We aim to train the people who will move the industry forward — in production, innovation and product development.”

Smart optical sensor detects ripeness for a quality drop

Queen Mary University of London researchers are developing a handheld, AI-powered grape ripeness...

Lighting up wine spoilage in real time with novel biosensor

A biosensor that glows when acetic acid is detected has been built by researchers to help...

Novel food processing technologies retain more nutrients in food

The potential of a range of modern techniques to improve the nutritional profiles of grain-,...