Intelligent packaging solutions for the bakery industry

There have been many advancements in the bakery industry in recent years, particularly in the area of process and packaging machines. Consumers are demanding more sustainable packaging, a shortage of skilled labour is making automation important, and energy and material efficiency are becoming increasingly competitive factors. Therefore, bread packaging solutions are required to be ecological, economical and technologically flexible in equal measure.

Sustainability is a crucial factor and many manufacturers are already focusing on recyclable, compostable or bio-based materials, such as paper-based solutions, PLA films or monomaterials. For example, at the interpack trade fare, exhibitor Weber Verpackungen will be showing its Baker Bag for self-service counters. The paper packaging can be equipped with viewing windows made of thin transparent recycled film or transparent paper (glassine). Using a glassine window makes easier for the bags to be recycled.

Product protection is another top priority for packaging to ensure that bread or cakes do not spoil prematurely. For this reason, innovative packaging systems need to primarily combine hygiene and shelf life with sustainability. Barrier functions that reduce the exchange of water vapour and oxygen, and thus keep the contents fresh, are particularly in demand for vending machine bags for the automatic packaging of bread and baked goods. Currently, these barriers can only be achieved when paper packaging is used by means of plastic coatings, film laminations or coatings with a polymer-containing layer. All the same, plastic content is lower than with a foil bag.

A parallel advancement to material development is the automation of packaging processes. Robotics and artificial intelligence are increasingly finding their way into production and enable precise, gentle handling of delicate baked goods. Modern systems work with camera-supported detection systems that analyse the shape, position and quality of the products in real time. This means that only flawless goods are packaged, waste is reduced and process reliability is increased. At the same time, changeover times are reduced — a decisive factor in view of smaller batch sizes and frequently changing product variants. interpack 2026 will present the latest technological developments and innovations to a broad trade audience.

Intelligent systems for large companies and SMEs

Digitalisation enables networks of machines, sensors and control systems in baked goods production to create intelligent overall systems. Process data such as temperature, sealing quality or material consumption are continuously recorded and automatically analysed. Platforms such as VisionAI use AI-based image analysis to immediately recognise deviations and adjust parameters in real time. Predictive maintenance is also becoming increasingly important: by analysing machine data, failures can be prevented and downtimes minimised. Such smart factory concepts are no longer the preserve of large companies, but are increasingly of interest to medium-sized baked goods manufacturers.

Robotics, sensor-based control systems and AI show their strengths when it comes to sensitive or irregularly shaped products in particular. Gerhard Schubert GmbH, for example, has developed the Cobot tog.519, a solution that combines AI-supported image recognition and flexible robot kinematics. The cobot picks up a wide variety of baked goods — even unsorted — at up to 90 cycles per minute. New product moulds can be integrated quickly using tools from the 3D printer, which reduces changeover times and investment costs.

Versatile packaging solutions for small batches are popular in the biscuit and baked goods industry. As many users also have limited floor space, systems with a compact layout are becoming increasingly important. This is where Schubert’s technology comes in, with manoeuvrable, space-saving robots. The French biscuit manufacturer Nutrition & Santé has already integrated such solutions into its production. The initial spark for the cooperation with Schubert was interpack 2023.

There, the packaging machine manufacturer presented a new, efficient feeding system for pre-cut parts of boxes. After the trade fair, Nutrition & Santé opted for a system with a flowpacker, cartoner and two single-lane A3 erectors, which packs a total of 13 different types of biscuits (including rectangular and round biscuits, chocolate-nut varieties and filled bars). The centrepiece of the system is the versatile TLM cartoner, which can flexibly handle seven bag formats and carton sizes.

Machine manufacturer Syntegon recently introduced a new counting system for the packaging of biscuits. The FGCT counting feeder is designed for gentle handling, greater efficiency and less product waste. The system groups biscuits in the desired quantity particularly gently and places them upright in trays or directly into the infeed of a flowpacker.

With its Alpha Wrapper systems, Fuji Packaging also offers practical solutions for sensitive baked goods with resealing options and opening aids. Space-saving, chainless film guides enable flexible handling, and the Fuji sealing technology ensures the processing of modern, sustainable and recyclable packaging materials. The Hamburg-based company, which has been selling flowpackers from Japanese manufacturer Fuji Machinery in Europe for over 40 years, also has various solutions for MAP packaging in its portfolio, such as the Pre-Vac system, in which the products are evacuated and then flushed with inert gas.

Process heat-sealable papers at high speed

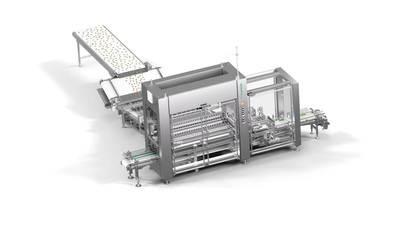

The industry’s innovative strength is also evident in high-performance packaging. JTM Foods, a leading US manufacturer of snack pies, is using JT Advance horizontal flow-wrapping machines with contactless feeding from the Italian manufacturer Sacmi Packaging & Chocolate in its new production facility. The fully electronic, servo-controlled systems can be configured for flat pouches, side-gusseted pouches, pouches with offset sealing, pouches with tear strip and on-edge packaging with longitudinal and transverse sealing. They can achieve up to 200 cycles per minute and use heat-sealable paper films. Individually 3D-printed forming shoulders prevent material breakage and enable high packaging speeds at a consistent level of quality. The system is complemented by compact secondary packaging solutions such as the IER 030 toploader and the F-EL carton erector, which are designed for high output in a limited space.

Multivac is breaking new ground in process integration with the Cooling@Packing system, a vacuum application that transfers the cooling process directly to the thermoforming packaging machine. Thanks to vacuum cooling, baked goods can be packaged immediately after baking, since the temperature drops from 95 to around 30°C within a few seconds. This saves energy, reduces the space required for cooling systems and minimises the risk of product contamination.

From 7 to 13 May 2026, visitors to interpack in Düsseldorf will be able to experience how sensitive baked goods are produced and packaged. For further information, visit www.interpack.com.

Dairy drinks maker installed aseptic PET packaging line at greenfield facility

A dairy business in India selected Sidel for its first aseptic PET packaging line which has been...

What's on trend for the packaging sector in 2026?

Jet Technologies' Daniel Malki says innovation and capability are advancing across packaging,...

Solving the limitations for paper packaging with coating strategy

Paper can provide a sustainable packaging alternative, but its poor resistance to water and oil...