An algae shake and a critter fritter please — ensuring there will be enough protein available to feed the world in 2050

It is estimated that by 2050 an extra 265 million tonnes of protein will be needed to feed the world’s population. This means that current production levels will have to be raised by about 50%.

Every adult needs about 60 g of high-grade protein each day. To feed the global population, agriculture produces some 525 million tonnes a year of plant products containing protein such as corn (maize), rice, wheat or soybeans. By 2050 this will need to increase to 790 million tonnes to account for the expected population increase.

To close the looming protein gap, Bühler and ETH Zurich (Swiss Federal Institute of Technology Zurich) have entered into a close cooperation: “Together, we plan to create the basis for the industrial utilisation of alternative sources of protein such as pulses, algae and insects to ensure a sustainable supply of food and feed for humans and animals and to make them attractive for consumers,” explained Ian Roberts, chief technology officer of Bühler. As part of this joint venture, Bühler is supporting the new chair of the Sustainable Food Processing Group at the Institute of Food, Nutrition and Health of the ETH Zurich, affiliated with the World Food System Center, Prof. Alexander Mathys.

Closing this protein gap is a serious challenge

Even for today, our protein supplies are not sustainable because we consume too much animal protein in the form of meat or fish. Two-thirds of all vegetable proteins produced end up in the stomachs of livestock such as cattle, pigs, poultry or fish. “Intensive farming, mass animal breeding and fishing do not cover our protein needs in a sustainable and environmentally compatible way,” said Roberts. “What we need are new, innovative approaches to protein production and processing. Otherwise, our agricultural systems face the threat of collapse,” added Prof. Alexander Mathys.

Although an increasing number of people enjoy eating meat and fish, there is no alternative in the long term to increasing the utilisation of plant proteins. High hopes are currently being pinned on pulses such as peas, lentils or beans. These gluten-free sources of protein are currently experiencing a revival, especially in Europe and North America, although they have always been part of the staple diet in Asian and African. Bühler offers systems that not only hull, split and sort pulses but also process them in their pure form or blended with other raw materials to make pasta, baked products, snacks or meat substitutes. Such novel products make pulses more attractive for a wider circle of consumers because they do not have to change their dietary habits.

In the medium to long term, however, the use of new raw materials is inevitable. Algae and insects especially stand out as high-grade sources of protein. Microalgae such as Chlorella or Spirulina (Arthrospira) do not compete with existing farming land, grow quickly and take up little space. Their high-quality protein may be processed, for instance, into food and animal feeds. Whole algae and algae extracts are already available in the marketplace today. They are consumed mainly in Asian countries, but are also highly appreciated in the West by a small community of particularly health-conscious consumers. If algae-based products are to appeal to a broad mass of western consumers, they will need to be integrated in traditional foods without significantly changing their taste and texture. In addition to proteins, algae also contain valuable polyunsaturated fatty acids and colour pigments.

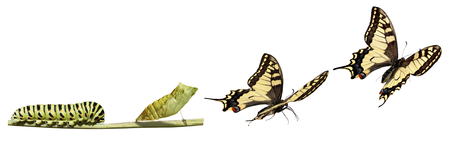

Further, insects such as mealworms or the larvae of the black soldier fly also hold major potential. They can be fed with industrial co-products or even certain types of waste and are astonishingly efficient: from 2 kg of feed, they build 1 kg of insect mass. Another benefit is their low space requirement. As a protein source, insect meal has similarities with fish meal. It could, therefore, revolutionise aquaculture as a sustainable source of feed and help reduce the pressure on natural fish populations.

Insects are considered a delicacy in Asia and are offered in the market in a similarly wide range as meat varieties and cuts are at a butcher’s store in western countries. Europeans and North Americans, admittedly, still often find insects repulsive. However, if their distaste can be overcome by suitable processing — into protein powder, for example — and if open issues regarding food safety, the legal situation and processing can be settled, insects may in the future become an extremely promising source of protein for human nutrition.

Bühler is currently setting up a pilot facility with a partner in China for processing fly larvae and mealworms on an industrial scale. Its aim is to produce insect flour as a replacement of fishmeal plus a high-grade fat with properties similar to those of palm kernel oil.

“The benefits of algae and insects are obvious. In designing integrated biorefineries for their cultivation and processing, it is important that we collaborate at an early stage with technology companies such as Bühler,” said Prof. Mathys, summarising the motivation for the collaboration of ETH Zurich with the Uzwil-based technology group. A lot of questions regarding industrial-scale cultivation, extraction and processing of algae or insect proteins still remain to be answered. Bühler possesses vast process engineering expertise, which could be put to use in such future processing and production systems. For instance, the Group has already demonstrated that the most cost-efficient mechanical method for rupturing algae cells today is by agitator bead mills. This wet grinding technology is also used for manufacturing printing inks or paints. It allows particularly gentle rupturing of the tough cell walls of algae for extracting and separating all the valuable constituents.

Eggless muffins using clean-label texturiser

Bakery solutions specialist Lasenor Emul, S.L. has crafted muffins with 50–100% less egg...

DNA base editing could enable better probiotic strains

Thanks to DNA base editing technology, researchers have created a strain of...

Tree sap: a plant-based gelatine alternative?

Researchers from the University of Ottawa may have found a new plant-based alternative to...