One Shot Loading: The untapped end-of-line opportunity

Most FMCG manufacturers have invested heavily in automating their processing and packaging operations. Conveyors, fillers, labellers and palletisers all work in tight synchronisation to move product efficiently through the plant.

But at the very end of the line — where product is dispatched to market — there’s often a hidden bottleneck.

The loading dock.

Despite decades of automation upstream, many manufacturers still rely on forklifts and manual labour to load trucks and containers. This not only slows down dispatch, it introduces safety risks, labour costs, and inconsistencies that undermine the efficiency of the entire operation.

Now, as industry focus shifts toward factory-to-freight optimisation, many manufacturers are asking: what if the final link in the chain could be automated too?

That’s where One Shot Loading comes in.

What Is One Shot Loading?

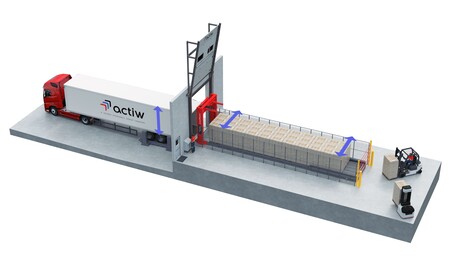

One Shot Loading is the automated transfer of full palletised loads — either with or without pallets — into trucks or containers in a single movement. It replaces multiple forklift trips with a streamlined system that can load a vehicle in 5–8 minutes, with no manual intervention.

The Joloda Hydraroll Group, a global leader in automated truck loading systems (ATLS), offers a comprehensive range of One Shot Loading technologies for different applications and industries. These include:

-

ACTIW LoadMatic, LoadMatic Lite & LoadPlate — typically for unmodified trailer systems and is ideal for warehouses using third-party logistics providers

- Joloda Slipchain, Trailerskate & Moving Floor — for modified trailer systems, ideal for shuttle runs and closed-loop logistics between known facilities

Through its ANZ partner Foodmach, Joloda now offers these systems to Australian manufacturers seeking to increase loading efficiency, reduce labour dependency and improve workplace safety.

Why Now?

FMCG facilities across Australia are hitting limits at the loading dock. Seasonal surges can overwhelm manual loading capacity. Labour shortages and forklift congestion add risk. And for those expanding, the cost of building and staffing large dispatch areas is only rising.

In modelling by the Joloda Group, a warehouse dispatching 300,000 pallets annually could lose up to 3% in deliveries during peak periods — equating to 9,000 missed pallets and significant lost revenue.

Automated loading removes this bottleneck by:

- Eliminating peak-season shortfalls

- Reducing manual labour requirements

- Improving safety and product handling

- Shortening vehicle turnaround times

- Reclaiming valuable floorspace

Modified vs Unmodified

A key consideration is whether trailers will be modified to work with the loading system.

Modified trailer systems (like Slipchain or Trailerskate) offer exceptional speed and repeatability, especially for shuttle runs between known origins and destinations — such as a processing site and centralised warehouse. These systems require some investment in trailer infrastructure but deliver exceptional ROI in dedicated logistics environments.

Unmodified systems (like LoadMatic and LoadPlate) work with standard trailers and containers, making them ideal for facilities that use third-party carriers, don’t control their outbound fleet, or need the flexibility to load a range of vehicle types. No structural changes are needed at the receiving end.

Both systems are proven in food manufacturing environments — and in some cases, even used together. At one European Heinz facility, for example, Joloda’s modified Slipchain system is used for high-speed shuttle runs while two Actiw LoadMatic systems handle third-party outbound freight.

Greenfield: Design it Right from the Start

In new builds, One Shot Loading offers powerful design advantages. Docks can be fewer and smaller. Forklift or AGV fleets can be significantly reduced with enhanced efficiency. Labour costs can be contained from day one.

Here’s a theoretical greenfield project: A major FMCG producer planned to run 35 loading staff across three shifts. By integrating two LoadMatic systems and redesigning the dispatch zone, they cut staffing needs to eight people and halved dock footprint. The projected savings:

-

AU$1.96M in annual labour costs

-

1–2 year payback

- Capacity to scale dispatch volume by 100% without added headcount or dock space

Brownfield: Bottleneck Relief Without Major Rebuild

Even older sites can benefit from One Shot Loading. In a theoretical Australian example, a manufacturer retrofitted a LoadMatic system into their existing warehouse to resolve peak-season loading delays.

With no staff reductions, the benefits came purely from throughput gains:

- 50% increase in pallet dispatch capacity

- Elimination of 3% peak-season under delivery

- Payback in under 4 years

- Improved safety, lower forklift usage and reduced trailer turnaround times

When expansion isn’t possible, automating the dispatch zone becomes one of the few viable ways to grow.

Additional Benefits

One Shot Loading isn’t just about speed — it’s about control.

-

Safety: Dramatically reduces forklift traffic in high-risk zones

-

Sustainability: Fewer forklifts, less fuel, less noise and emissions

-

Consistency: Pallet loads are always positioned correctly, reducing damage

-

Flexibility: Systems like LoadPlate can handle fragile, irregular or high-value goods

- Scalability: Adding loading capacity doesn’t always mean adding docks or headcount

Partnering with Foodmach

As an official ANZ partner for the Joloda Hydraroll Group, Foodmach offers integration expertise across a full range of automation technologies — from pack to dock. Supplying advanced technologies over the entire span of a packaging line and now, One Shot Loading, Foodmach provides support with:

- Site assessment and layout design

- Integration with warehouse control and ERP systems

- Equipment supply, installation and commissioning

- Ongoing service, support and upgrade pathways

Is Your Site a Fit?

One Shot Loading is most effective for:

- Sites dispatching 200+ pallets per day

- Manufacturers managing seasonal surges

- Operations with tight labour markets or safety goals

- New builds or warehouses due for upgrade

- Businesses balancing owned and outsourced freight

Whether you’re running dedicated shuttle trailers or relying on third-party logistics, Foodmach and the Joloda Hydraroll Group can recommend the best-fit solution — modified or unmodified — to streamline your dispatch operations.

Learn more about One Shot Loading at www.foodmach.com.au

Or contact sales@foodmach.com.au to discuss your application.

Advanced inspection systems that go above and beyond to safeguard food

To effectively safeguard food safety and quality, food manufacturers must employ the most...

Boost Efficiency with Weidmüller PUSH IN Terminal Blocks

Weidmüller PUSH IN terminal blocks are engineered to deliver reliable and efficient...

Mettler-Toledo Launches X3 Series to Transform Bulk Flow Inspection with Advanced Detection, Hygienic Design and Precision Rejects

X13 and X53 x-ray inspection systems deliver sharper detection, precision rejects and digital...