IAL sets new standard in food production with Rittal Hygienic Design Enclosures

Australia and New Zealand’s food and beverage industry operates under stringent hygiene and compliance regulations to uphold product safety and quality. With automation playing an increasingly vital role in production, safeguarding critical equipment against high-pressure washdowns, water ingress and bacterial contamination is essential for maintaining operational integrity and regulatory compliance.

Meeting these hygiene standards requires robust, compliant equipment that can withstand rigorous cleaning processes while protecting critical automation systems. Integrated Automation Limited (IAL), one of New Zealand’s leading automation solutions providers, sought a reliable enclosure solution for their accumulation conveyor system in the food and beverage industry.

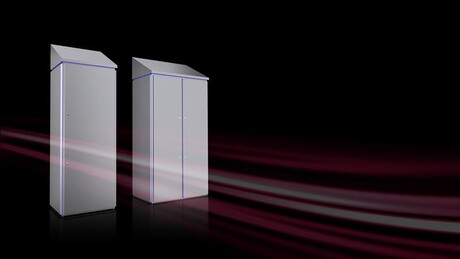

Rittal’s Hygienic Design (HD) enclosures provided the perfect solution, offering durability, compliance and visual appeal. This project marked IAL’s first use of the HD series, which has since become the standard for their automation solutions across the food and beverage industry.

Addressing Hygiene and Durability Challenges

Food production environments pose unique challenges for automation systems, where hygiene, durability, and reliability are critical. IAL needed enclosures that could:

- meet strict hygiene regulations — ensuring easy cleaning, resistance to bacterial growth, and suitability for food-contact environments;

- withstand aggressive cleaning processes — protecting against hot water and chemical exposure, which could cause corrosion and water ingress;

- manage temperature fluctuations — preventing condensation buildup, which could affect automation performance;

- ensure system reliability — protecting critical automation components to reduce downtime and maintenance costs.

To address these challenges, IAL turned to Rittal’s Hygienic Design enclosures, a solution engineered specifically for hygiene-critical production environments.

Rittal’s Hygienic Design Enclosures: Built for Food Production

Rittal’s Hygienic Design enclosures provided a comprehensive and reliable solution tailored to the needs of food production facilities.

Key features include:

- Stainless steel construction: High-grade stainless steel with a smooth finish offers resistance to corrosion and damage from cleaning agents while enhancing the system’s professional appearance.

- Sloped roof design: The 30° sloped roof prevents water pooling during cleaning, reducing bacterial growth risks and ensuring compliance with hygiene regulations.

- Blue door seals: FDA-compliant, food-safe silicone gaskets create a secure seal that prevents contaminants. The distinctive blue colour simplifies hygiene inspections.

- Quick-release fasteners: Hexagon fasteners ensure easy access for maintenance without compromising the hygienic seal.

- Customisation and modularity: Modular enclosures allowed IAL to customise the setup for their automation components, ensuring seamless integration with the accumulation conveyor system.

Setting the Standard for Automation

The successful implementation of Rittal’s Hygienic Design enclosures provided IAL with a durable, compliant and reliable enclosure solution, ensuring uninterrupted operations.

“The HD series has a superior design, high-quality stainless-steel construction, hygienic blue seals and gaskets that add to the quality. We build world-class automation systems that add value to our customers’ profitability and business growth. Protecting the automation components in the control cabinet is essential to prevent downtime,” said Donovan Ryan, Managing Director, IAL.

Following this success, IAL standardised Rittal’s HD enclosures across its food and beverage automation solutions, setting a new industry benchmark for hygiene-focused automation systems.

As the food production industry evolves, investing in hygienic, durable and efficient enclosure solutions is critical to maintaining compliance and operational excellence. Rittal’s Hygienic Design enclosures deliver long-term reliability for hygiene-critical environments.

Looking to enhance hygiene and efficiency in food production automation? To learn more, download our brochure.

Advanced inspection systems that go above and beyond to safeguard food

To effectively safeguard food safety and quality, food manufacturers must employ the most...

Boost Efficiency with Weidmüller PUSH IN Terminal Blocks

Weidmüller PUSH IN terminal blocks are engineered to deliver reliable and efficient...

Mettler-Toledo Launches X3 Series to Transform Bulk Flow Inspection with Advanced Detection, Hygienic Design and Precision Rejects

X13 and X53 x-ray inspection systems deliver sharper detection, precision rejects and digital...