Pilz PNOZmulti 2 controllers for burner management applications

In the food processing industry, where thermal systems are central to production, ensuring the safe operation of burners and furnaces is not just best practice — it’s a regulatory necessity. With increasingly stringent safety standards such as EN 298, EN 50156 and NFPA 85/86, manufacturers must rely on certified solutions to maintain compliance and protect both personnel and equipment.

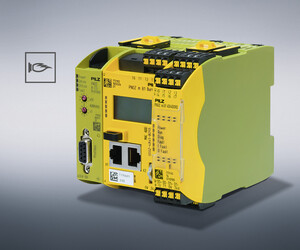

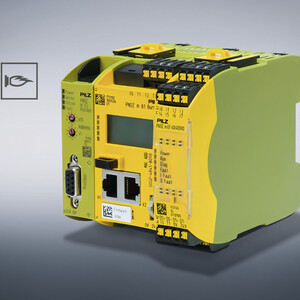

The PNOZ m B1 Burner, a specialised base unit within the PNOZmulti 2 family of modular safety controllers from Pilz, is designed precisely for this purpose. Though not a new product, it remains a relevant solution for Australian food manufacturers seeking to modernise or reinforce their burner safety systems.

This compact controller is supported from version 10.12 of the PNOZmulti Configurator software and includes a dedicated burner function block. This software element replicates the functionality of a configurable electronic automatic burner control, enabling users to implement a wide range of burner applications with ease. Whether managing master or slave burners, direct or indirect ignition, or low and high-temperature operations, the PNOZ m B1 Burner offers the flexibility to adapt to diverse system requirements.

The burner function block has been tested and certified in accordance with key European safety standards, and further international certifications are underway. This is designed to ensure that the system not only performs reliably but also meets the compliance needs of global operations.

One of the key advantages of the PNOZmulti 2 system is its modularity. The PNOZ m B1 Burner can be expanded with modules such as the PNOZ m EF 4DI4DORD, which provides four safe inputs and four diverse, positively guided relay outputs — suitable for controlling safety valves in burner systems. Additional modules, including safe analog input units, allow for comprehensive monitoring and control of the entire furnace set-up.

From a safety performance perspective, the system supports applications up to Performance Level PL e / Category 4 according to EN ISO 13849-1, and Safety Integrity Level SIL CL 3 in line with EN/IEC 61508. The base unit is certified by internationally recognised bodies including cULus, CE, TÜV, EAC and KOSHA, making it suitable for deployment across a wide range of markets.

Beyond its technical capabilities, the PNOZ m B1 Burner offers practical benefits for engineers and plant managers. It simplifies the design and implementation of complex safety applications, reduces engineering time, and integrates smoothly with existing automation environments and communication systems. With the ability to control and monitor up to 12 burners from a single unit, it provides a scalable and cost-effective solution for both new installations and system upgrades.

For more information, click here: (Systems for safe burner control - Pilz AU) or email: sales@pilz.com.au.

Phone: 1300 723 334

GEA CookStar spiral oven

GEA expands CookStar portfolio with compact spiral oven for small to mid-sized food production.

Alfa Laval Clariot AI-based condition monitoring solution

The AI-based condition monitoring solution Clariot from Alfa Laval provides 24/7 surveillance and...

Pil P53 series Hygienic Ultrasonic Sensor

The PiL Sensoren P53 series of ultrasonic sensors is designed for applications with stringent...