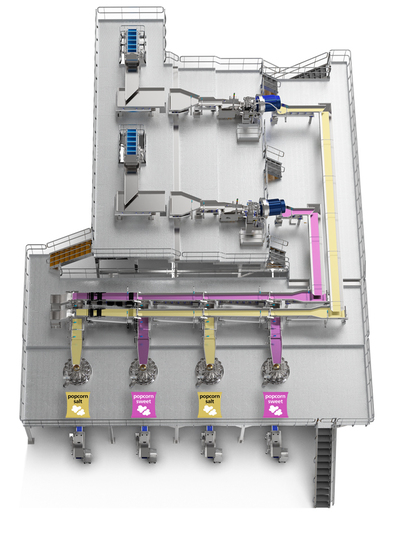

Making sweet and salted popcorn with no changeovers

A leading popcorn manufacturer in the UK wanted to scale production and elevate product quality — without adding complexity.

The manufacturer had specific requirements of fast throughput for small bags and the flexibility to run both sweet and salted popcorn simultaneously. Ultra-low flour salt dosing with consistent coverage was a key requirement and it also wanted to keep waste to a minimum.

TNA delivered a fully integrated distribution, seasoning and packaging line that runs: 140 bags/min on 11 g bags; under 1% waste; and sweet and salted production at the same time with no changeovers.

With innovations like automatic kernel and sugar clump removal, ultra-low flour salt dosing, and dual-line seasoning, the system has raised product quality and throughput to a new level.

A suite of innovations was integrated to enhance both product quality and line productivity. An airbridge system was installed to automatically eject unpopped kernels and sugar clumps before seasoning — ensuring only safe, quality product reaches the flavouring stage.

With dual in-line seasoning, the system can handle sweet and salted profiles simultaneously, without the need for changeovers. An antistatic drum prevents ultra-fine flour salt from sticking, preserving precise seasoning accuracy, while a flow control auger enables ultra-low salt dosing with good consistency — no auger swaps required. The open platform design also improves operator access and line visibility, making cleaning and daily operation faster, simpler and more ergonomic.

Phone: 02 9714 2300

Fishbowl AI cloud-based operations platform with new AI Manufacturing capability

Featuring an embedded AI assistant, 'Juno', Fishbowl's new cloud-based platform is...

Krones UniPure S decanter technology

With the UniPure S, Krones is expanding its UniPure product family to include decanters.

Key Technology ADR X for potato strips

Key Technology has introduced its new ADR X automatic defect removal system for potato strips.