Blending operations boosted using rotary batch mixer

EW Packaging contract manufactures and packages powder, tablet and capsule products, protein powders, energy drink mixes and sports nutrition products. Customers include national warehouse clubs and dietary supplement retailers.

Founded in 2001 as EW Trading (DBA EW Packaging), CEO Rob Lonas renamed it EW Packaging when he brought the company’s packaging and printing services in-house. Today EW operates six blister-filling lines and four bottle-filling lines and uses flexographic printers to customise pouch and blister foils. It also machines its own tooling, which shortens turnaround times and reduces costs.

In 2016, the company began blending dietary supplement and food powders and manufacturing tablets and capsules, but its V-cone blender proved inefficient. “The machine was a lot of work and there was a lot of downtime,” Lonas said. “It took at least 30 minutes to get a load in and out, plus another 15 to 20 minutes of actual mixing.”

Next, he tried a ribbon blender, which reduced loading and unloading times but compromised blend quality. “The ribbon blender has corners, dead zones, where the powder isn’t mixed,” he said. Sometimes EW added as much as 10% more active ingredient to the products than required for HPLC testing to confirm that the product met the label claim. In addition, the ribbon blender’s impeller put product quality at risk, Lonas said. “It chops up the ingredients and damages the product at the same time.”

Gentler, more accurate blending

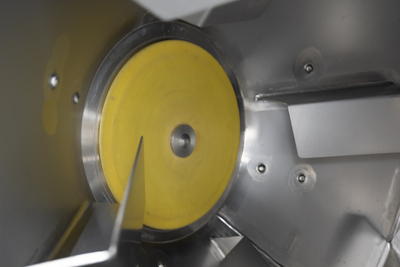

To improve EW’s blending operation, Lonas purchased a 425 L Munson Rotary Batch Mixer that loads, blends and discharges in about 15 min — half the time of the previous blenders. The unit’s horizontal vessel rotates on external trunnion rings located at each end, handling ingredients gently because it has no agitators. Instead, the vessel has internal flights that create a four-way tumble-turn-cut-fold mixing action, producing homogenous blends without generating heat, shear or stratification. Lacking internal shafts, the mixer has no seals that are in contact with the product.

To initiate a blending cycle, operators hand-weigh ingredients into a drum. A plant-based protein product may contain up to eight ingredients, while a flavoured creatine product may contain up to four. The drum containing the weighed batch is then lifted onto a mezzanine and dumped through a security screen into a hopper that discharges into the mixer’s stationary inlet. A collection hood contains fugitive dust during the loading process, while a single external seal prevents the escape of dust during vessel rotation.

Lonas highlights the Rotary Batch Mixer’s gentle mixing action in his business conversations. “It’s part of my sales pitch for whatever the job is — encapsulation, tableting or just blending a powder,” he said. “This mixer just folds in the ingredients. It’s not smashing them or pounding them together.”

Blends are discharged from the mixer through a stationary outlet. Batches destined for encapsulation or tableting flow into mobile hoppers that are rolled into the adjacent room for those processes. Powder products are discharged into a screw conveyor that transports the batch to the feed hopper of an auger filling machine, which dispenses it by weight into bottles, canisters, tubs or almost any other container.

The vessel leaves almost no residue following discharge. “There aren’t any corners or pockets that can collect powder,” Lonas said. Between blending campaigns and when switching products, operators wash, rinse and swab-test the vessel interior in accordance with Good Manufacturing Practices.

Lonas said that the blends are always on-spec, and overages range between 2 and 3% instead of 10% previously. “I sold my V-blender and my ribbon blender. The Rotary Batch Mixer gives us a perfect HPLC test every time.”

Small size, big output

Despite its modest volumetric capacity, the mixer outputs high volumes because it loads and discharges quickly and blend times are short, as little as 3 to 6 min, Lonas said. “When we started getting bigger orders, we got nervous at first thinking our mixer wasn’t big enough, but we ran some big orders with no problems.” In one case, EW Packaging blended some 80 batches of a protein powder over four days, filling all of it into 2.3 kg tubs.

“The future for us is growing the powder business because we have our powder lines so dialled in. It’s a profitable and a fast way to fill bottles.” The company’s fastest line fills as many as 50,000 bottles a day, which includes capping, induction sealing, metal detecting, check-weighing, labelling, lot coding and neck banding.

“We seldom tell customers ‘No’ unless they come in with a liquid,” Lonas said. “If we don’t have the right machinery, we buy it. Our niche is getting new products going for people and cranking it out, getting them into the market fast. We get a lot of business because of our blister capabilities and because we can do short-run stuff. There aren’t many other places on the West Coast that can do that.”

Lonas calls the mixer his workhorse. “I think we changed a seal once. There’s not much maintenance to do on it. It’s one our most reliable machines.”

Phone: 03 8792 0200

Krones UniPure S decanter technology

With the UniPure S, Krones is expanding its UniPure product family to include decanters.

Key Technology ADR X for potato strips

Key Technology has introduced its new ADR X automatic defect removal system for potato strips.

GEA CookStar spiral oven

GEA expands CookStar portfolio with compact spiral oven for small to mid-sized food production.