Pumping particles is no problem

By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Tuesday, 15 March, 2022

Pumps are an integral part of many food processing facilities, but care must be taken to select the correct pump for both the product being moved and the process requirements. Physical damage to the product, as well as the influence of factors such as pressure and shear stress, must all be taken into account. When you wish to pump large solid items, such as fruit and vegetables, these challenges become even greater.

There are many types of pumps on the market, including rotary lobe, rotary piston, reciprocating positive displacement, progressing cavity, peristaltic hose and air-operated double diaphragm designs. However, not all of them are capable of maintaining product quality at a reasonable cost while keeping the required pressure in the system (in particular, progressive cavity pumps can break the product, while double diaphragm pumps result in a low pressure drop). Furthermore, traditional pumps can be expensive to maintain while lobe pumps have low flow rates.

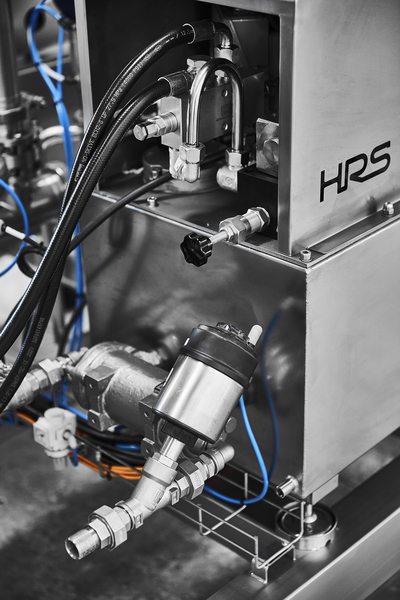

To overcome these difficulties, HRS developed the BP Series of hygienic reciprocating, positive-displacement pumps, which are suitable for a wide range of difficult-to-handle food products, including whole peppers, strawberries and baby carrots, as well as sauces, dips, fruit purees and many others.

Positive displacement pumps have an expanding cavity on the suction side of the pump and a decreasing cavity on the discharge side. Liquid flows into the pump as the cavity on the suction side expands and is forced out of the discharge side as the cavity collapses. The HRS BP Series Piston Pump is operated either hydraulically or pneumatically (depending on available air supply pressure) and incorporates a separator fitted between the piston and the hydraulic chamber to ensure that there is no contact between the product chamber and the hydraulic oil (if fitted).

The standard BP Series has an adjustable flow rate of between a minimum of 200 L/h and a maximum of 12,000 L/h and features a high pressure drop of up to 30 bar. It is suitable for a wide range of high-viscosity, shear-sensitive and large-particle-containing fluids. Clap valves allow pumping of whole fruits or vegetables and an alternative piston pump with a pneumatic cylinder can be supplied for low pressure applications of less than 5 bar.

Over the years three additional models have been added to the BP Series range:

- BPM Series — a skid-mounted, mobile version allowing it to be used across multiple production lines.

- BPSC Series — designed for highly viscous products, and those which are produced and packed at low temperatures, it features a screw conveyor to feed the pump inlet.

- BPH Series — a horizontal version with a vertical inlet and a ball valve instead of a clap valve.

The HRS BP Series is designed to meet many challenges, whether processing whole fruits or vegetables, delicate dairy products like creams and sauces, highly viscous materials such as hummus or larger particles such as coleslaw or fruit compote.

Smart optical sensor detects ripeness for a quality drop

Queen Mary University of London researchers are developing a handheld, AI-powered grape ripeness...

Lighting up wine spoilage in real time with novel biosensor

A biosensor that glows when acetic acid is detected has been built by researchers to help...

Novel food processing technologies retain more nutrients in food

The potential of a range of modern techniques to improve the nutritional profiles of grain-,...