Biodegradable packaging solution that's berry good

University of Queensland researchers have developed a biodegradable plastic that could be used as a sustainable alternative for mass-produced food packaging such as fruit punnets — potentially replacing the 580 million or so plastic punnets currently being used every year.

After three years in development, the biocomposite has been successfully tested as a strawberry punnet that biodegrades completely in soil, fresh water, the ocean and in compost. And berry punnets are just the beginning for the material which is envisioned for a range of food packaging and other rigid plastic applications.

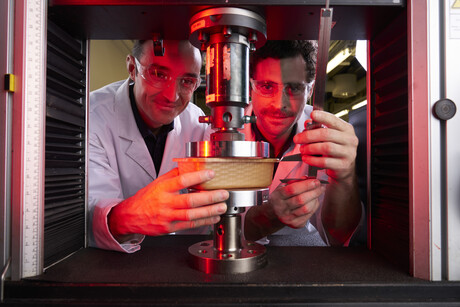

Fermented from bacteria and strengthened with Australian wood fibres, the novel biocomposite was produced by PhD candidate Vincent Mathel and Dr Luigi Vandi at UQ’s School of Mechanical and Mining Engineering as a commercial alternative to petrol-based plastics.

“This is a new material that carries all the sustainability benefits of a bio-sourced product while having the same properties as mass-produced plastic packaging and containers,” Mathel said.

“It was also important to us to make a biocomposite that maximises Australian resources to have the added environmental benefit that it does not need to be imported from overseas.”

Mathel and Vandi have been perfecting their biocomposite within UQ’s Centre for Advanced Materials Processing and Manufacturing (AMPAM), backed by an assortment of industry collaborators and an Advance Queensland Industry Research Fellowship.

The team created the material by blending bacteria-produced biodegradable polyesters known as polyhydroxyalkanoates (PHAs) with wood fibres taken from radiata pine sawdust.

Mathel said the team selected wood as the ‘biofiller’ to flesh out the plastic because it was abundant, low in cost, and could enhance the end of life standard for biodegradable and compostable products.

“The thing many people don’t realise is that bioplastics are not always bio-based and not always biodegradable — there is a lot of greenwashing,” Vandi said.

“If you are striving for complete sustainability and add natural ingredients to the mix, you can impact the physical qualities of the bioplastic, and its suitability for everyday use.

“Getting the balance right is very important.”

The team then turned to its partners biotech Uluu and Brisbane-based injection moulding firm SDI Plastics to help with a manufacturing run of 200 strawberry punnets.

Kulbir Dhanda, who was based at SDI Plastics, was integral to the process.

The Queensland Strawberry Growers Association and Mandy Schultz from LuvaBerry Farm were also enlisted to ensure the new biocomposite met end-user requirements for a product that typically has a very high packaging-to-fruit ratio.

“Punnets are pretty bad from a sustainability perspective, but they are the only way to effectively ship and sell strawberries without ruining the fruit,” Vandi said.

Mathel said the team was now compiling data on the end-of-life composting of their packaging in collaboration with Phoenix Power Recyclers, led by senior environmental scientist Dr Deepak Ipe and general manager Chris Alexander.

“The ultimate goal is to phase out petrol-based plastics,” Mathel said.

“But bioplastics will play a crucial role as a solution when plastics are unavoidable, especially for short-term applications.”

The researchers are looking for financial backing to establish manufacturing for the new biocomposite.

The research is published in Composites Part A: Applied Science and Manufacturing.

Clariant achieves EU approval for renewable additives in food-contact plastics

The specialty chemical company said it achieved EU Commission approval based on the EFSA opinion...

Opal Packaging Plus partners with Phantm to develop packaging compliance solution

Opal Packaging Plus has partnered with Phantm to build a data asset to help future-proof...

Making sweets with added benefits

interpack 2026 conveys a resounding message: the confectionery industry is changing — in...