Coca-Cola bottler in India boosts capacity for high season

With more than 240 million residents, Uttar Pradesh in the north of India is the most populated state on the subcontinent. The climate is also extreme: during the hot months of March to July, temperatures can soar to a maximum of 50°C — making it the high season for the beverage industry.

Coca-Cola India’s production and distribution are managed entirely by independent regional bottlers. The largest of these is SLMG Beverages, a consolidation of four bottlers all run by brothers of the Ladhani family of entrepreneurs. They’ve worked for Coca-Cola in Uttar Pradesh and its neighbouring regions for more than 30 years. Through the takeover of a further bottler, SLMG Beverages recently also secured the licence for the state of Bihar. This means that in the future the company will supply around 350 million people with soft drinks.

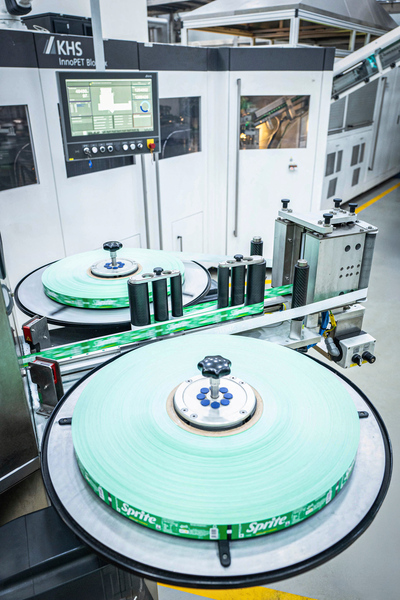

One of its eight associated filling facilities is located in Chhata, and the newest of the six beverage lines in Chhata was delivered and installed by KHS. The heart of the line is the InnoPET TriBlock, a modular block system comprising a stretch blow moulder, roll-fed labeller and filler. It processes up to 48,000 non-returnable PET bottles an hour holding between 250 mL and 2 L. During the high season, the main focus is on small single-serve formats. The bottling plant now fills approximately 15.4 million containers per annum.

“In 2023, our output rose by almost 35% over the previous year and in 2024 we again grew by 25%,” said Sriharsha Chilukuri, who is senior general manager of the plant. “We produce approximately 60% of our soft drinks in PET bottles on the new line.”

KHS and SLMG Beverages have been working together for a long time. “We’ve been procuring machines from KHS since we started bottling for Coca-Cola,” Chilukuri said.

The most recent examples are two Plasmax machines that coat the insides of PET bottles with an ultra-thin layer of glass. This protects the contents against oxygen pickup and carbon dioxide loss, thus preserving the product’s taste and extending its shelf life. The Dortmund systems supplier was now able to secure the companies’ first joint line project with its InnoPET TriBlock. Various technological aspects, such as efficiency and an in-house roll-fed station for hot-melt, wrap-around label application, formed the key criteria for being awarded the contract. The promise of quick project implementation in time for the start of the high season ultimately clinched the deal; it’s during these few months that the company makes about 80% of its annual turnover. Just 40 days passed from delivery of the machines through installation to validation of the first bottle — an exceptional tempo, according to Chilukuri.

The local team at KHS’s Indian production site in Ahmedabad in particular have every right to be proud of this achievement: besides supplying the conveyors and palletisers manufactured themselves onsite, they also handled the installation and commissioning of the line. “During acceptance, the line ran for 10 hours without disruption,” said Dharmesh Baria, project manager for after sales and service at KHS. “This amounts to a performance of 99.96%.”

Besides the technology, Chilukuri primarily appreciates the good relations enjoyed by the two companies. “Our relationship goes beyond the usual OEM/customer cooperation. As business partners, we’re on an equal footing and see ourselves as a team that works as one.” One important reason for this is KHS’s local presence. “This is a distinguishing criterion. KHS’s experts are available to us at any time and we can rely on getting exactly the kind of support we need.”

It’s clear that SLMG Beverages has big plans: over the last few years, the bottler has invested almost €400 million in plant engineering. To date, the enterprise has grown annually by around 20 to 25%. The plan for 2025 has been to boost its turnover to over a billion euros — not least thanks to its recent regional expansion.

Phone: 03 9335 1211

KRAIBURG TPE FC/CM3/AD1 compound series

The KRAIBURG TPE FC/CM3/AD1 compound series with adhesion to polar thermoplastics is designed for...

Sidel EvoBLOW Laser

Sidel introduced the EvoBLOW Laser to the Middle East at Gulfood Manufacturing 2025.

Packserv four-head, 5 L pneumatic filling machine

The pneumatic filling machine is suitable for food, pharmaceutical, HACCP and TGA-compliant...