Leuze introduces the DRT 25C diffuse sensor with CAT technology

By Dr. Marie-Theres Heine – Germany Product Manager – Binary Switching Sensors

Monday, 01 February, 2021

Leuze’s detection expert — the DRT 25C — can meet the high requirements of packaging machines for confectionery and baked goods with innovative reference technology.

With the DRT 25C dynamic reference diffuse sensor, Leuze has brought a new operating principle to the market of switching sensors. At the heart of the invention is CAT technology, which transforms a simple diffuse sensor into an intelligent device. This can be seen in the DRT 25C’s mode of operation: it is taught on a reference surface at the press of a button. It can then reliably detect nearly every object — independent of shape, colour and surface structure. What serves as the reference surface is anything available in the given application environment, such as a machine wall, a piece of sheet metal, or even a vibrating, moving conveyor belt. This makes the sensor particularly well suited for packaging systems, especially in confectionery and baked goods. No readjustment is necessary when changing objects.

Leuze developed its first own optical sensor almost 60 years ago. Numerous technological milestones and innovations have followed since then. The more than 1200 Sensor People worldwide view themselves as forerunners for their customers. Leuze has registered more than 200 patents in the last ten years alone. The goal is to ensure the lasting success for their customers in an industry that is ever-evolving. Not only do the Sensor People have decades of experience, but also in-depth application know-how in their specific focus industries.

With throughputs of several hundred thousand products per day and finely tuned process steps, the packaging industry can place high demands on optical sensors. Clear-glass retro-reflective photoelectric sensors require less maintenance through smart tracking. This is thanks to line-shaped light spots and laser diffuse sensors, which detect objects on its front edge. Powerful through-beam photoelectric sensors can also detect the chocolate bar in its outer packaging with harmless infrared light. The CAT technology, which the new DRT 25C dynamic reference diffuse sensor uses, continues the idea of the clever sensor.

The goal: detection on a running conveyor belt

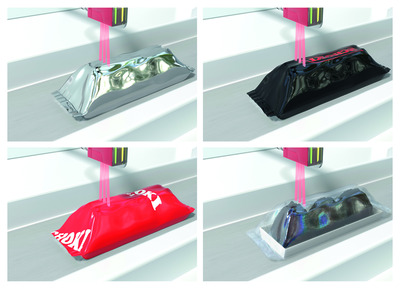

Packaging and the objects to be packaged vary widely in colour, shape and surface structure: flat, glossy, with openings or transparent — the entire spectrum. As a result, they can be challenging to detect. But precisely that is the task of optical sensors in packaging systems. The challenge in object detection is detecting as quickly and reliably as possible, and ideally directly from above. At the same time, the working environment also poses a challenge. The objects that are to be detected are usually on conveyor belts that move and vibrate, leaving them open to becoming soiled or wet. The sensor solutions currently on the market have only been able to perform this task to a limited extent. Therefore, there was an opening in the market for a more intelligent model.

CAT technology: Contrast Adaptive Teach

This market requirement led to the development of CAT technology at Leuze. CAT stands for Contrast Adaptive Teach. The underlying idea is simple: if the object can change at any time, use its environment as a constant reference surface. In packaging systems, this is the conveyor belt. This serves as a teachable reference. Once the sensor has been taught the contrast information of the conveyor belt, it only needs to be intelligent enough to adapt this knowledge to a possible change of environment.

Operating principle of dynamic reference diffuse sensors

The DRT 25C dynamic reference diffuse sensor uses the CAT technology in a new operating principle: it learns the conveyor belt's signal parameters at the press of a button and stores them as the standard zero. Every object that is transported on the conveyor belt now generates a signal. If this deviates from the zero state, the DRT 25C reliably detects the object as a deviation from the reference. The performance of the device is optimised through the choice of teach level.

There is, for example, a teach routine for conveyor belts that becomes heavily soiled over time. Another teach level exists especially for the detection of very flat or transparent objects. Once the sensor has been taught, no additional settings or readjustments are necessary. Not even if the object is changed, as the sensor operates together with the conveyor belt as a reference.

Reliable detection increases the throughput

If, for example, a chocolate bar is not reliably detected, a mishap quickly occurs in the subsequent, precisely cycled packaging, which must then first be removed and cleaned. The more reliably the sensor detects the product, the less frequent unplanned maintenance needs to be performed. Herein lies the strength of the DRT 25C dynamic reference diffuse sensor, which operates reliably even with complicated shapes and surfaces. This increases the machine throughput, the production quantity and avoids downtime. Because no adjustment work needs to be performed on the sensor when changing products or changing the packaging materials, setup time is also reduced, further increasing output quantities. Up to now, a format change — such as from the classic 100 gram bar of chocolate to a mini chocolate cube — meant that sensors had to be readjusted. But because the DRT 25C uses the conveyor belt as a reference, this is no longer necessary. Even if the colour, height or contour of the packaging changes, no settings need to be made on the dynamic reference diffuse sensor.

The all-rounder based on CAT technology

The DRT 25C dynamic reference diffuse sensor represents a new operating principle that is based on CAT technology. It thereby sets new technological standards on the market and is another milestone in the innovation history of Leuze. The Sensor People thereby precisely meet their customers’ requirements for reliable detection and make them successful in an industry that is ever-evolving. After all, the success of its customers is the company’s aspiration and goal. Reduced downtimes, increased machine throughput, and higher production quantities, all with maximum flexibility without readjustment when changing objects — that means increased cost-effectiveness for its customers.

For more information, visit https://www.leuze.com.au/DRT25.

The AI Advantage: Why Food Manufacturers Can't Afford to Wait

Rapid technological change is reshaping Australia's food processing sector, leaving...

Handmade Food + High-Growth Systems: How Fishbowl scaled up Adelia's Operations

A regional success story built on craftsmanship and creativity.

The Inside Scoop: How Fishbowl Boosted Lick Ice Cream's Sweet Success

Lick Ice Cream is focusing on efficiency and traceability with the help of Queensland-based...