Temperature monitoring device supports Aussie winery

When establishing Jansz Pontos Hills Winery in Tasmania’s Coal River Valley, Hill-Smith Family Estates looked to a temperature monitoring solution that was simple, reliable and future-ready — without the need to rely on specialist engineering and maintenance expertise.

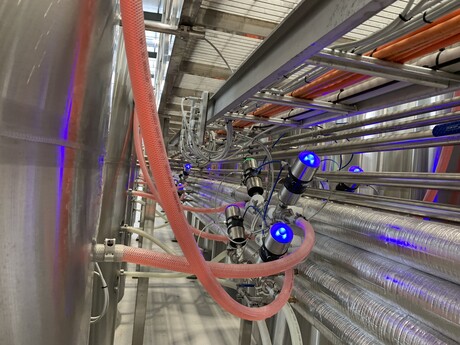

ifm efector responded with its user-friendly IO-Link enabled temperature monitoring devices.

According to Luke Wilson, Manager — Engineering, Services & Cellar Operations, Hill-Smith Family Estates, this solution has since been adopted as the new instrumentation standard for the Hill-Smith Family Estates.

“We selected the ifm IO Link solution for our temperature control management system because of its ease of installation,” Wilson said.

Building the system on the IO-link network has enabled the winery team to be able to quickly and cost-effectively replace faulted probes, valves and hardware with only minimal electrical knowledge required. This suited the winery’s requirement for remote support — especially as there was no technical or engineering support on-site at the Pontos Hills Vineyard.

Instead of relying on time-consuming manual checks, the Jansz Tasmania winemaking team (and their engineering specialists at the other locations) could access the system remotely, receiving real-time data and early alarms that enabled them to make immediate adjustments.

This approach gave the team greater confidence during the vintage season, enabling faster, more precise winemaking with less downtime.

“A lot of wineries have temperature control in the form of a probe and a valve on a tank,” Wilson said. “But what inevitably happens is that the valve will fail or something happens so that the tank is no longer under control, but the winemaker’s not aware of it. The ifm solution comprises smart sensors that have given us the ability to react before there’s any impact on the quality of the product.”

The continuous monitoring enables precise temperature control, reducing wastage. The winemakers could optimise operations to power down equipment during peak energy demand periods, easing pressure on the grid and reducing costs. This will result in a more efficient use of resources, lower energy consumption and a clear reduction in the winery’s carbon footprint.

“Empowered with the system’s smart, proactive monitoring and maintenance functions, the facility reduced the risk of downtime and costly faults,” said Darryl Blackeby, Regional Sales Manager (SA/WA) of ifm efector.

“This installation showcases how ifm adapts its advanced technologies to new contexts, extending beyond traditional automation into the specialised world of winemaking,” Blackeby said. “Our solution is simple, affordable, non-invasive and easy to adopt, enabling producers to introduce digital monitoring without disrupting their craft. It delivers measurable performance gains and environmental benefits, empowering industries to innovate with confidence.”

Phone: 03 8561 0500

Key Technology ADR X for potato strips

Key Technology has introduced its new ADR X automatic defect removal system for potato strips.

GEA CookStar spiral oven

GEA expands CookStar portfolio with compact spiral oven for small to mid-sized food production.

Alfa Laval Clariot AI-based condition monitoring solution

The AI-based condition monitoring solution Clariot from Alfa Laval provides 24/7 surveillance and...