Hyperspectral imaging for food grading

Food manufacturers are under increasing pressure to deliver high-quality products with full traceability, zero defects and minimal waste. With tight margins and growing consumer scrutiny, the industry is looking for smarter, more versatile inspection systems that go beyond surface appearance.

Hyperspectral imaging (HSI) has emerged as a suitable technology in this space, providing a good depth of information from every pixel in a product image. By combining spectroscopy with machine vision, HSI enables producers to see both what’s on the surface and what is invisible to the human eye and conventional machine vision inspection tools. It is designed to assess quality grades, detect contaminants, inspect seals and integrate seamlessly into existing production lines. Inspection is non-contact and non-destructive, and it can deliver real-time, actionable data in a repeatable fashion.

This article explores how HSI is being used in three aspects of food manufacturing: product performance grading, food safety assurance and industrial adaptability.

1. Measuring product performance and quality

HSI is a powerful tool for grading food products based on performance-linked quality parameters. It works by capturing reflectance spectra across hundreds of narrow wavelength bands, far beyond the visible spectrum, revealing structural and chemical features invisible to the human eye or traditional RGB cameras.

This enables non-destructive, real-time measurement of, for example:

- Moisture, fat and sugar content

- Protein levels and pH

- Ripeness, texture and firmness

- Bruising, chilling injury and internal defects

- Product homogeneity and composition

In fruit and vegetable processing, for example, HSI systems can automatically grade apples by sugar content (Brix), firmness and bruising, all while they move on a conveyor belt at high speed.

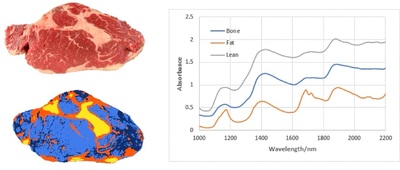

In meat and seafood, HSI can be used for assessing marbling, fat distribution, tenderness and colour, all of which affect flavour, shelf life and price.

Beyond raw materials, HSI is also being used to validate formulation in processed foods, ensuring that blended ingredients or emulsions meet quality expectations. By analysing the ‘spectral fingerprint’ of each pixel, manufacturers can detect whether a product is uniform throughout or if layers, concentrations or segregation has occurred.

Because HSI systems acquire spatial and spectral data simultaneously, they allow food processors to visualise not only the constituent ingredients of a product, but also how these are distributed, helping to ensure consistency and performance across standardised product lines, ultimately increasing consumer satisfaction.

2. Ensuring food safety with spectral vision

Food safety is an area where hyperspectral imaging can add value. HSI systems are capable of detecting a wide range of foreign bodies, contaminants and chemical adulterants that traditional vision systems or X-ray machines may miss, especially those that mimic the colour or shape of real food.

Applications include:

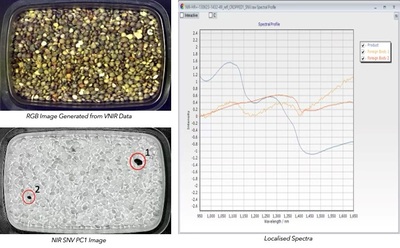

- Plastic fragments in grains, cheese or baked goods

- Bone or shell fragments in meat and seafood

- Detection of stones, wood and other contaminants in harvested goods

- Fungal contamination (eg, aflatoxins or fusarium)

- Melamine in powdered dairy products

- Faecal or ingesta contamination on poultry

HSI systems are also finding applications in non-food object detection, such as identifying insects or packaging debris that may have entered the product stream during processing. Because the detection is based on spectral characteristics rather than contrast or density, even translucent or colour-matched materials can be flagged reliably.

Moreover, HSI has the potential to inspect package integrity: identifying seal defects, product stuck in seal, leaks or residues that compromise product safety. Recalls can cause reputational and financial damage, so having a high-speed, chemical-sensitive inspection system on the line can be game changing.

3. Built for industry: speed, adaptability and ROI

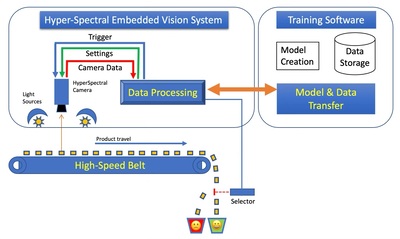

HSI has historically been seen as a research or lab-based tool, but is now evolving into a more adaptable and agile solution. New-generation push-broom HSI systems are engineered for industrial readiness, offering robust performance in demanding environments.

Key features include:

- High-speed line-scanning suitable for conveyor lines

- Integration with PLCs and automation frameworks

- Real-time data acquisition and spectral classification

- Hygienic, steam-cleanable stainless steel enclosures for demanding environments

- User-friendly software with calibration model management

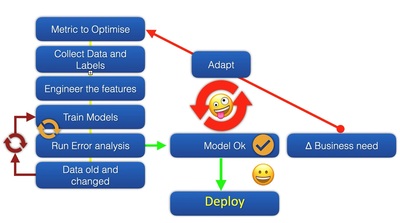

The key strength of HSI in food quality and security lies in its lab-to-line workflow. Typically, a product is first analysed in the lab, where spectral models are built and optimised to predict a specified quality or detect a specific contamination. Once optimised and tested, these models are uploaded to the inline HSI system, which performs live inspections and flags products outside the accepted tolerance: ‘the good, the bad and the ugly’.

If production reveals further new or unexpected defects, the system can pull those examples back to the lab, engineers can update the model and close the loop, hereby creating an iterative, learning-based quality assurance process.

Rather than relying on sampling and averages, HSI enables 100% inspection of products at production line speeds, empowering processors to make smarter, faster decisions to reduce waste and increase profit.

Hyperspectral imaging can help to change the face of food quality and safety inspection. By moving beyond surface appearance to measure both structural and chemical properties, HSI can enable food manufacturers to deliver premium quality, ensure safety and reduce waste, all the while maintaining high throughput and product repeatability.

From grading performance-linked parameters like sugar or fat content to detecting invisible contaminants or package seal issues, HSI can provide a robust, repeatable and ever-adaptable platform. With industrial-grade systems now available for full inline deployment, this once niche lab tool is becoming a mainstream technology.

See it in action

The team from ClydeHSI will be visiting Australia from the 3–14 November for a demonstration tour. They’ll be bringing a selection of their advanced hyperspectral imaging systems and will be available to conduct onsite evaluations using customer samples. For more information, please contact Quark Photonics, the local distributors for ClydeHSI, via sales@quarkphotonics.com.au.

Smart optical sensor detects ripeness for a quality drop

Queen Mary University of London researchers are developing a handheld, AI-powered grape ripeness...

Lighting up wine spoilage in real time with novel biosensor

A biosensor that glows when acetic acid is detected has been built by researchers to help...

Novel food processing technologies retain more nutrients in food

The potential of a range of modern techniques to improve the nutritional profiles of grain-,...