How can food manufacturers halve waste?

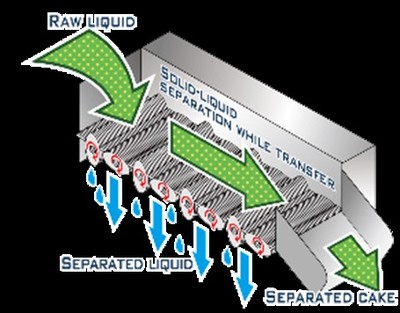

The CST Wastewater Solutions KDS separator system was displayed at the recent FoodTech Qld exhibition. It is designed to remove 50% of the water from wastewater sludge, creating a more compact output ready for transport to a treatment centre.

“Food and beverage companies are highly aware of the need to dispose of waste responsibly. But small-to-medium operations can’t afford to install expensive processing, compacting and drying plants at their own facilities, so they need to have it carried to a dedicated treatment centre — usually by road. That’s where the costs can start to add up with sodden or wetter wastewaters,” said Michael Bambridge, Managing Director, CST Wastewater Solutions.

“Compacting the wastewater onsite prior to transportation can lead to significant savings, particularly when you consider that it can cost upwards of $150 a ton to move by specialised transport.”

The smallest separator system available is approximately 250 mm wide with throughputs of one cubic metre or one tonne every hour, depending on the application. The clog-free automatic technology is suitable for compact dewatering applications including: food processing waste, seafood processing and abattoir, feedlots and dairy farm wastewater and sludge.

“The machine can be placed into existing facilities without the need for a major upgrade of the overall space,” Bambridge said.

Used for thickening of dissolved air flotation sludge, the KDS liquid-to-solid separator is claimed to achieve solids capture of 97% thickened sludge at a dryness of 17%. Waste activated sludge dryness levels are typically 15–25%.

Phone: 02 9417 3611

ProMinent DULCODOS SAFE-IBC F&B metering and emptying station for intermediate bulk containers

The DULCODOS SAFE-IBC F&B from ProMinent has been specially developed for the requirements of...

Flexicon PNEUMATI-CON dilute phase vacuum conveying system

Flexicon's PNEUMATI-CON dilute phase vacuum conveying system is designed to facilitate...

Tru-Gard Flex Barrier System

Tru-Gard has released Tru-Gard Flex, a patented barrier system designed to provide impact...