Wrap? Shrink? Stretch? Comparing pallet packaging systems

For companies in the food, chemical or building material industries, the efficient packaging of their palletised goods is a deciding competitive factor. Factors to be considered include transport security, anti-theft protection, display characteristics of the packaged goods and weatherproofing for outside storage. Further key factors are process efficiency and cost reduction, as well as the system output.

There are three different palletising packaging techniques on the market: shrink hooding, stretch wrapping and stretch hooding.

Efficient packaging with shrink film

For shrink hooding, the film is produced as a tube using blow head extruders with tubular dies, which are then further processed or slit open to become a flat film. Hot air heats the film during the shrinking process up to the softening point. The film is shrunk to fit perfectly around the palletised goods, which, after cooling down, creates the necessary stability to secure the load. The heat required for the shrinking process is produced by the packaging system either electrically or with gas.The pallet can be packaged with its base open for the skids of the forklift, allowing high-bay storage, or the film can be drawn over the pallet base. The shrinking method is particularly suitable for products that are sensitive to elastic packaging stacking, such as glass. The goods are reliably protected against environmental impacts; however, the shrinking process causes the film to become milky, which makes it difficult to see the goods or imprinted barcodes. Polyethylene (PE) bags might weld to the packaging film and the heat effect can be a fire hazard.

Or opt for wrapping instead?

The stretch-wrapping technique is one of the most popular solutions with many companies, due to the low initial investment costs for the machines. This technique, however, requires a lot of material, which requires frequent changes of the film roll.

The film’s elasticity solidifies the palletised goods during packaging; however, the technique provides little vertical tension force to the load, which is needed to provide stability. This technique is not suitable for materials with sharp edges, and additional plastic film is required to protect goods against environmental impacts and humidity. The film overlay prevents an optimal display of the products and barcodes on the film cannot be read easily. The film attracts dirt particles due to its adhesion properties and the products collect dust during longer storage periods. The film does not offer any protection against theft as goods can be removed from the pallet without ripping the film. Projecting film remnants can disturb the sensor system of the conveying technology or the rack feeders, causing error messages. Due to the many setting parameters, the quantity of the film required for the packaging cannot be calculated exactly.

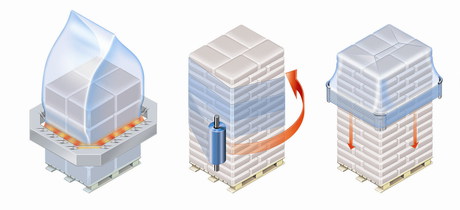

High transport security with stretch hoods

The stretch hood technology is a combination of the film hood and stretch-wrapping techniques.

Like shrink hooding, the stretch film adapts to any product that is stacked on the pallet. And similar to wrapping, the film is very elastic and therefore solidifies the material via contracting forces, giving high load stability. The film is not glued to the product during the process, and it is possible to pack the pallet either for high-bay storage systems or with understretch. The smooth film surface ensures high visibility of the packaged goods and therefore provides a good display of the packed goods, with barcode labelling quickly recognisable.

The used film is recyclable, less film and energy are required and, as stretch hooding does not use heat, the fire hazard is reduced. It allows for a clean and dry outdoor storage, protecting goods against environmental impacts, humidity, insects and UV rays.

Weighing the costs

Engineers from BEUMER Group compared shrink hooding to stretch hooding on a palletised test stack 1630 mm in height. The shrink-hooding system processed 35 to 70 pallets/hour, with film strength between 120 and 180 micrometres. Using the stretch-hooding method, throughput was nearly doubled with 100 to 120 pallets/hour, with film strength between 70 and 140 micrometres. Less material was required due to the elasticity of the film.

Based on the 2014 market price for shrink film of €1.70/kg, the packaging costs for a film hood were approx. €1.02, equating to approx. €306,000 for 300,000 pallets/year.

The film used for stretch hooding was slightly more expensive at €1.90/kg in 2014. As less film is required, the cost to form a film hood was €0.57. This equates to a cost difference of approx. €159,000 for 300,000 pallets, a cost saving of 52%.

Tailored solutions

Each product has its own handling characteristics, which require careful analysis by the user, to determine the pallet packaging requirements. Calculating the economic efficiency of different packaging techniques should take into account the individual energy consumption, as well as the maintenance, investment and system costs.

Lotte Chilsung opens fully automated beverage DC

Dematic has successfully deployed an advanced integrated logistics solution at Lotte Chilsung...

Safer, smarter and faster: automation delivers at Coca-Cola’s Brisbane warehouse

Coca-Cola's warehouse in Brisbane needed a flexible warehouse and palletising system that...

A sweet solution: Swisslog automates confectionery handling for Mondelēz

Swisslog has installed a warehouse automation solution for Mondelēz as part of its $130m upgrade...