Roll over porridge: wheat could rival oats and barley for lowering cholesterol

Wheat-based products are far more popular with consumers than oats or barley, but until now wheat could not make the ‘lowers cholesterol’ claim that makes the other grains attractive.

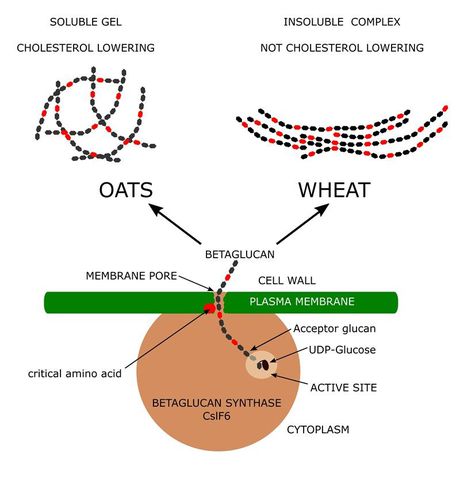

Barley and oat grains contain high levels of betaglucan. In these grains the polysaccharide is soluble and can lower cholesterol reabsorption in the gut, resulting in healthier blood cholesterol levels and lowering the risk of heart disease.

Wheat not only contains less betaglucan than that found in barley and oats, but its betaglucan has a slightly different structure that renders it insoluble so it does not offer health benefits.

To lower cholesterol reabsorption in the gut, betaglucan needs to be both soluble and viscous, and these properties are related to the betaglucan structure.

Betaglucan is made by an enzyme that sits in the membrane at the surface of the plant cell. This enzyme links activated glucose sugars from within the cell and extrudes the growing betaglucan chain through a pore in the membrane into the cell wall surrounding the cell.

A single amino acid difference at the base of the membrane pore controls the betaglucan structure, making it more or less soluble.

CSIRO researchers have improved understanding of how betaglucan structure is controlled and this could lead to the development of healthier wheat grains with higher levels of soluble betaglucan.

The researchers examined what controls betaglucan structure by expressing the betaglucan synthase gene (also known as CslF6) from each of the different cereals (wheat, barley, Brachypodium (a model plant), oat, rice, maize and sorghum) in the leaves of tobacco, a plant which does not contain any betaglucan.

By examining the structure of betaglucan produced in the tobacco leaf, the cereals could be grouped into two classes: one including oats and the other including wheat. By mixing and matching bits of the CslF6 protein from each of the two groups, the region of the betaglucan synthase that controls the structure was identified.

It turns out that the shape of the membrane pore through which the betaglucan exits the cell controls the polymer structure. In fact it is just a single amino acid difference at the base of the membrane pore which controls the betaglucan structure, making it more or less soluble. It is thought that this difference in shape changes how the glucan acceptor chain (the end where the next glucose molecule will be added) is presented to the active site altering the frequency of β1-3 and β1-4 bond formation and hence overall structure.

This groundbreaking study was published in Science Advances: Membrane pore architecture of the CslF6 protein controls (1-3,1-4)-β-glucan structure.

Future experiments will look at the possibility of screening for variation in the wheat CslF6 genes or using new gene editing technologies to produce the desired single amino acid change in the protein in order to increase the solubility of wheat betaglucan.

As wheat is consumed by a large proportion of the population on a daily basis and in much greater amounts than barley or oats, wheat grain with high levels of soluble betaglucan could have high socioeconomic impact by bringing heart health benefits to the community.

Rice being explored as a 'clean label' thickener

Polyphenols and proteins from pigmented waxy rice are being explored as a natural alternative to...

Whey to go: upcycling dairy waste into a beverage

Arla Foods Ingredients has launched a fermented beverage concept that demonstrates how dairies...

Arla Foods Ingredients to cut carbon emissions with heat pump technology

The ingredients manufacturer is investing in an electric heat pump facility at its primary...